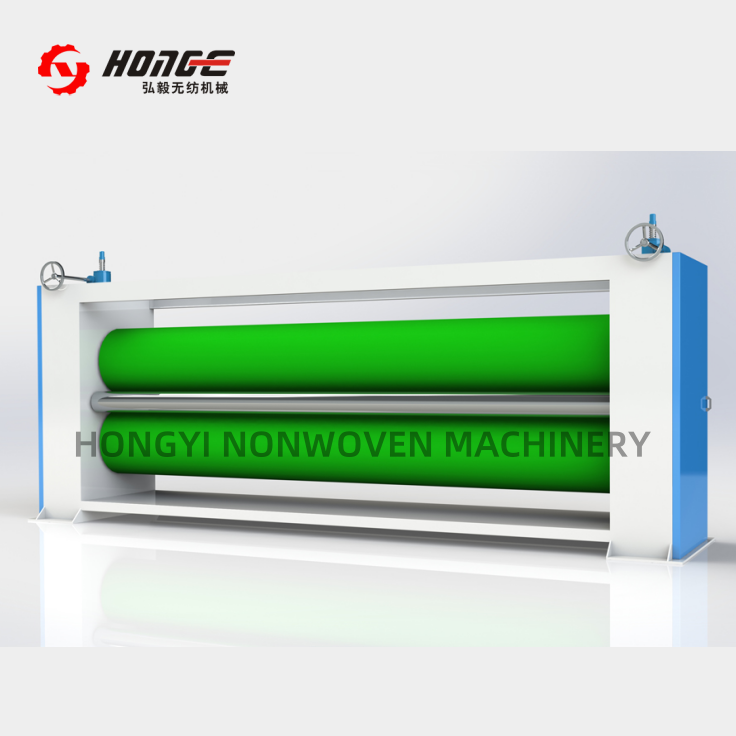

Double Doffer Nonwoven Carding Machine

Product description

Product Details

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HongYi |

| Certification: | CE /ISO9001 |

| Model Number: | 450PJM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiation |

| Packaging Details: | NUDE OR WOODEN CASE |

| Delivery Time: | 7DAYS AFTER RECEIVING THE PAYMENT |

| Payment Terms: | T/T, L/C, Western Union, Western Union, MoneyGram |

| Supply Ability: | 1 LINE 30 DAYS |

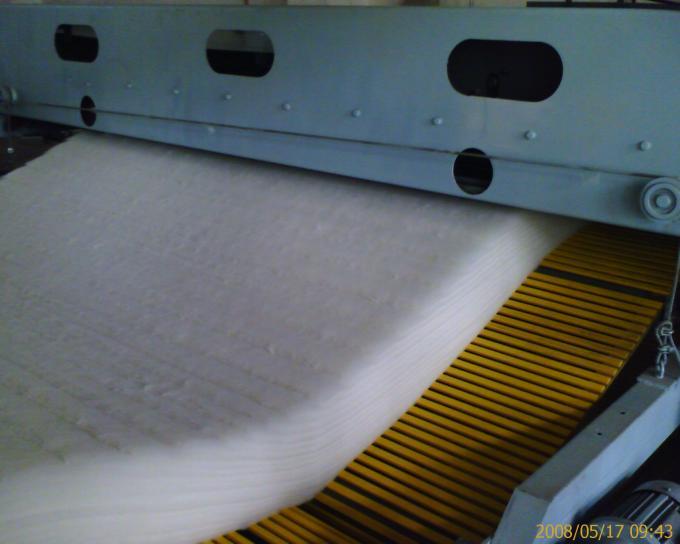

Double Doffer Nonwoven Carding Machine

Description

| Material: | Cotton/Yarn/Fiber/Textile Waste | Material Capabilities: | Fiber |

|---|---|---|---|

| Machine Type: | Double Cylinder Double Doffer | Width: | 1550-3200mm |

| Speed: | Max. 70m/min | Advantage: | High Production Capacity |

| High Light: |

OEM Nonwoven Carding Machine,Double Doffer Nonwoven Carding Machine,70m/min polyester fiber carding machine |

||

Nonwoven Carding Machine For Polyester Fiber Quilt Production Line

Non-woven Mechanical Application

- Medical supplies: Surgical masks, disposable clothing, surgical drapes, shoe covers, etc.

- Technical engineering :Civil engineering, construction engineering, agricultural field, automobile field, etc.

- Medical supplies: Surgical masks, surgical drapes, etc.Combined with other types of non-woven fabrics

- Sanitary materials: Baby diapers, adult incontinence pads, women's sanitary pads, other cleaning applications.

- Packing supplies: Shopping bags, rice bags, tea bags, clothing packaging and so on.

- Household goods: Spring - wrapped cloth, bedding, seat supplies, etc.

- Paper composite materials, etc. Work protection, protective clothing, gas masks, etc

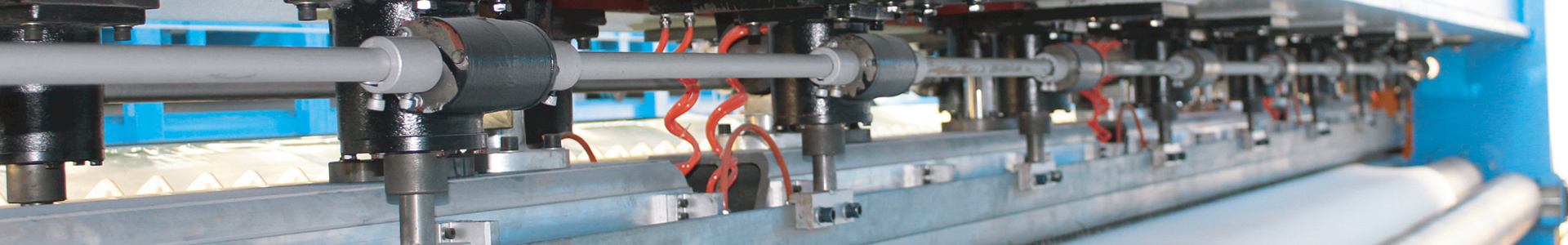

Principle: fiber is fed to feed conveyor from front feed equipment (such as pneumatic tuft feeder )and forms a thicker fiber web, then flocks are fed to breast cylinder by feed roller and taker-in, then transferred to the main cylinder by transfer roller. 8 pairs of carding units (worker rollers and stripper roller )are equipped on breast cylinder and main cylinder for opening and carding fiber, fiber which on the main cylinder is stripped onto the upper and lower web-out conveyor by stripping roller after passing doff and condenser roller, forming uniform web and feed to next machine.

Structure

|

item

|

value

|

|

Marketing Type

|

New Product 2020

|

|

Automatic Grade

|

Full-automatic

|

|

Voltage

|

380/440V

|

|

Power

|

40kw

|

|

Certification

|

CE/ ISO9001

|

|

Working width

|

1550mm, 1850mm, 2000mm, 2300mm, 2500mm, 3200mm

|

|

Production Capacity

|

800kg/h

|

|

Diameter of cylinder

|

1230mm, 850mm

|

|

Suitable fiber

|

1.5D-15D*38mm-64mm

|

|

Output speed

|

Maximum 70m/min

|

- Product: soft wadding

- Product net width : up to 4500mm(or wider dependent on individual requirement )

- Product weight:60-1500g/m2

- Product thickness :3-200mm

Pre-Sales Service

* Inquiry and consulting support

* Sample testing support

* View our factory

After-Sales Service

* Training how to install the machine , training how to use the machine

* Engineers available to service machinery overseas

* Warranty :12 months

* Certificate : ISO9001 CE

Trade information

* Payment terms: 30%deposite by TT, LC , Western Union ,Moneygram 70% as balance paid before delivery LC

* Delivery time: Approx 7 working days after receiving the rest payment

* Package: make, wooden case

* Warrantty:12 months

* After-sales service: we will send 2-3 workers to do the installation and commissioning of the line at the request of the buyer . and the buyer should provide round-trip airplane tickets , accommodation, and allowance, the allowance is 70USD /person/day

* HS code:84490090

* MOQ: 1set

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time