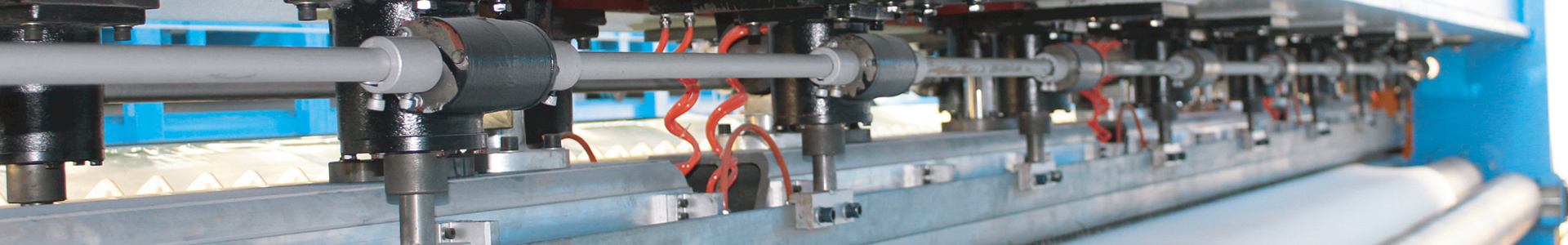

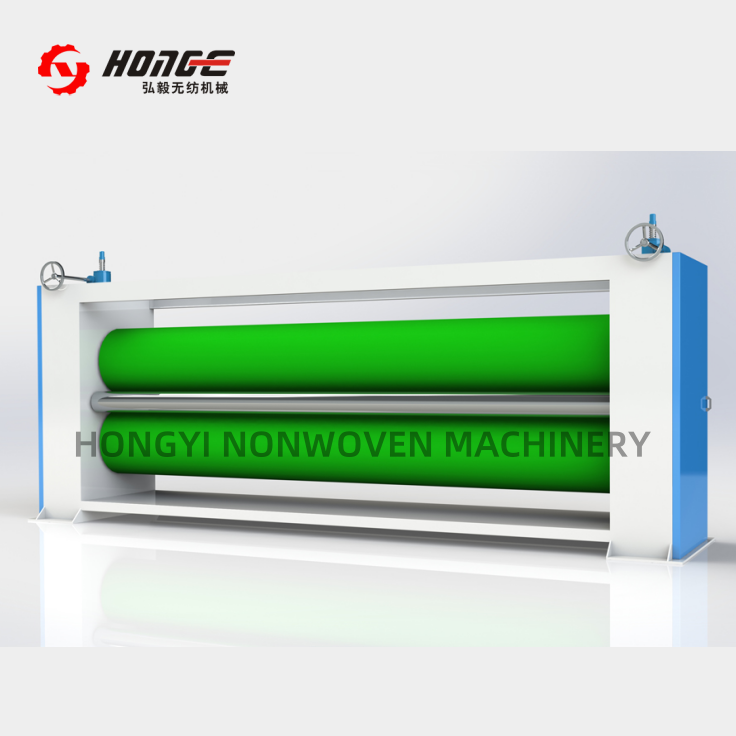

Synthetic PU Leather Nonwoven Needle Punching Line

Product description

Product Details

Product Details:

| Place of Origin: | china |

|---|---|

| Brand Name: | hongyi |

| Certification: | ce/iso |

| Model Number: | 2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiation |

| Packaging Details: | nude or case |

| Delivery Time: | 7days after receving the deposite |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 set 15days |

Synthetic PU Leather Nonwoven Needle Punching Line

Description

| Type: | PET Spun Bonded | Application: | PET Spun Bonded |

|---|---|---|---|

| Stroke: | 750rpm | Working Width Of Machines:: | 2000mm-8000mm |

| Production Capacity: | 100kg/h-1000kg/h Depends On Material And Final Product. | Certification: | Ce/iso |

| High Light: |

2000mm needle punching line,Nonwoven Needle Punching Line,hongyi needle punch machines |

||

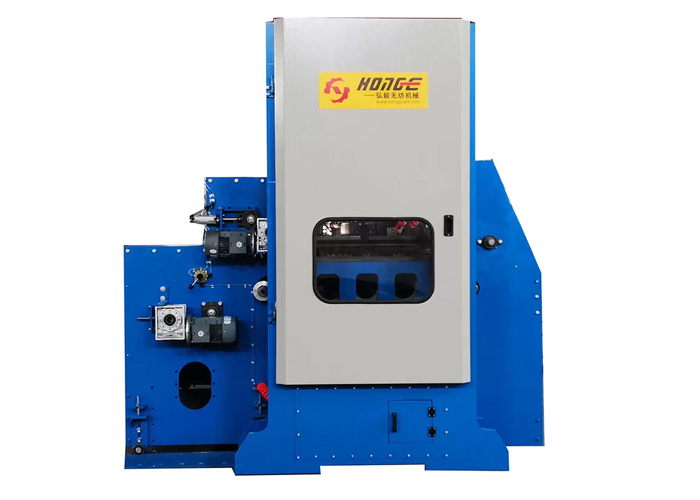

Synthetic PU Leather Making Machine/ Nonwoven Needle Punching Production Line

Main Features

1) Simple structure in linear type, easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Working width of machines: 2000mm-8000mm

Production capacity: 100kg/h-1000kg/h depends on material and final product.

Weight range of final product:

- 10gsm-150gsm for spunbond nonwovens

- 60gsm-800gsm for soft wadding product

- 80-5000gsm for hard wadding product

- 500-5000gsm for air laid waste felt product

- 100-1000gsm for needle punched felt

Suitable raw material: polyester fiber, PP fiber, waste fiber, jute fiber, cotton, wool, low melt fiber, coconut fiber for needle punching line and thermal bonding line; PP chips for spunbond production line and melt blown production line.

Applications: geotextile, carpet, synthetic leather substrate, shoe materials, quilts, blanket, mattress, bedding, comforter, mask, baby diaper, etc.

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time