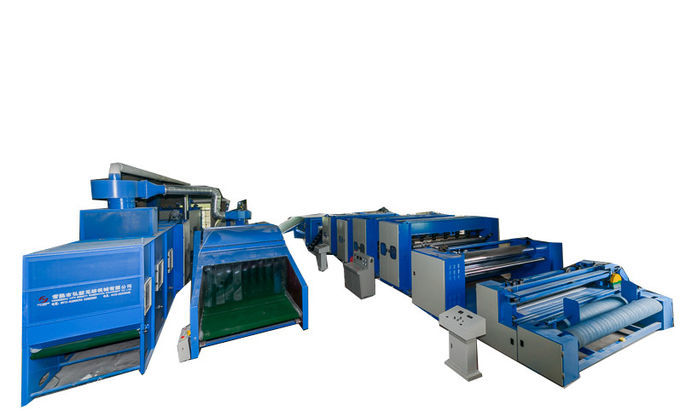

HONGYI Non Woven Carpet Needle Punching Machine

Product description

Product Details

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | HONGYI |

| Certification: | ISO9001/CE |

| Model Number: | HYGZ |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiation |

| Packaging Details: | PE film. |

| Delivery Time: | 90 days. |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per 90days |

Spunbond Non Woven Needle Punching Machine Meltblown Line

Description

| Width: | 2000-7200mm | Automatic Grade: | Automatic |

|---|---|---|---|

| Frequency: | Max. 1300rpm | Needle Density: | 3000-7000n/m |

| Stroke: | 30-70mm | Suitable Material: | Polyester Fiber, PP Fiber, Low Melt Fiber, Jute Fiber, Glass Fiber, Etc. |

| High Light: |

7200mm non woven needle punching machine,ISO non woven needle punching machine,30mm meltblown nonwoven fabric machine |

||

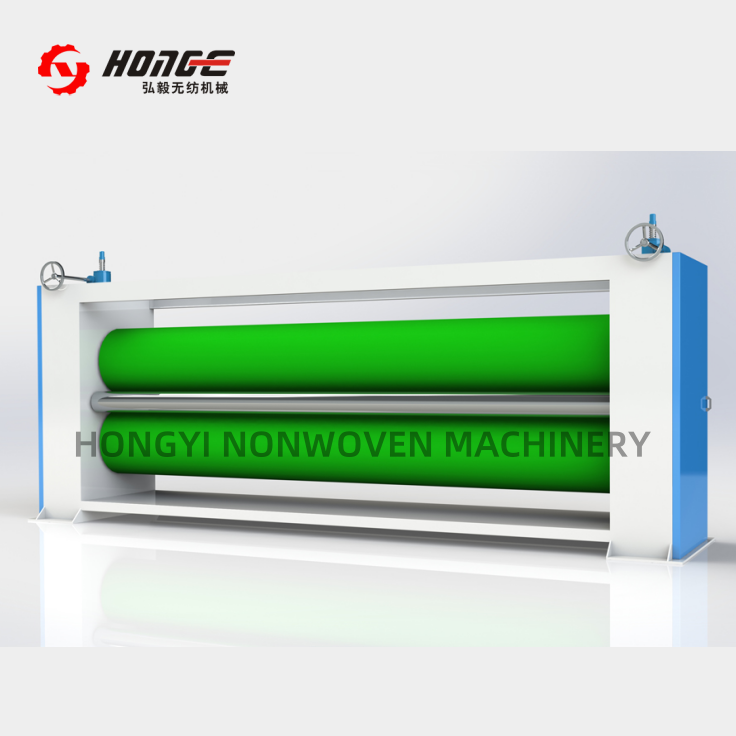

Spunbond Needle Punching Nonwoven Meltblown Line Fabric Making Machine

1. Automated and frequency conversion controlled

2. Advanced combined structure enables the excellent stabilization

3. Computerized random distribution of needles

4. Separated lubrication system

5. Easy operation and convenient maintenance

Technical parameters:

| Working width | 1500-8800mm |

| Needle stroke | 30-70mm |

| Needle density | 3000n/m-7000n/m |

| Needle frequency | Max. 1300rpm |

| Machine type | Single shaft single board, double shaft single board, double shaft double board |

| Installed power | Depends on the product requests. |

| Line speed | 1-10m/min |

| Needle board | Aluminum-Magnesium alloy plate |

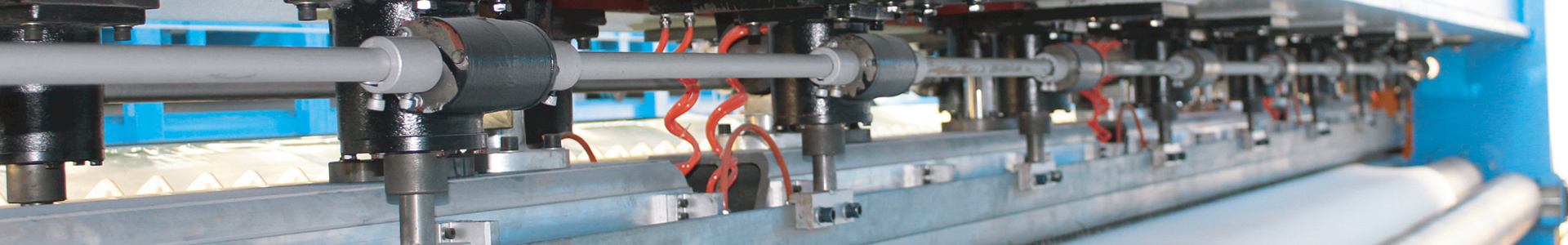

Structure characteristics:

a) Frame structures, to form by high quality armor plate welding.

b) It adopts single principle axis structure with single needle board.

c) Needle beam, working beam are high temperature shaped and precision processed.

d) Materials of main shaft adopt alloy steel, and made finely after high quality finishing.

e) The lifting and dropping of the bottom plate and stripper plate is controlled by electromotor and scale display.

f) Needle plate adopts Aluminum-Magnesium alloy plate, three plates with irregular computerized perforating.

g) The bottom plate and stripping plate with surface plated by hard chromium and polished.

h) Input and output roller with surface chrome-plated and controlled by separate frequency conversion.

Application:

The main applications of needle punched nonwoven materials are carpets, decorative felts, sports mats, furniture pads, shoes and hats, shoulder pads, synthetic leather base fabric, coated base fabric, ironing pads, filter materials, geotextile products, paper making blankets and so on.

It can also be used for automotive interiors, roofs and other insluation materials.

Trade information:

| Trade terms | FOB, CNF, or CIF |

| Lead time | 90 days after deposit. |

| Payment terms | 30% advance payment, 70% paid off before delivery. |

| Warranty | twelve (12) months after mechanical and electrical commissioning. |

| After-sale service | The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition the buyers should assign translator, workers, electrical cable (from machines to control panel and from power to control panel) and tools for installation to cooperate with the work. Installation cost is USD180/Day/engineer and totally installation period is about 30-40 days depending on well cooperation of the buyer. |

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time