Single Layer 15m/Min Thermal Bonding Machine Nonwoven Mattress Making

Product description

Product Details

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HONGE |

| Certification: | CE/ISO9001 |

| Model Number: | HYHX |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiation |

| Packaging Details: | NUDE AND WOODEN CASE |

| Delivery Time: | 15DAYS AFTER RECEIVIBF DEPOSITE |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 SER 7DAYS |

Single Layer 15m/Min Thermal Bonding Machine Nonwoven Mattress Making

Description

| Name: | Nonwoven Thermal Bonding Oven Machine | Width: | 1600-3800mm |

|---|---|---|---|

| Product Width: | 2.0m-3.2m | Work Speed: | 1-15m/min |

| Voltage: | 380V, 50HZ | Temperature: | 250℃ |

| Length: | 6m, 8m, 10m, 12m | Usage: | Make The Fibers Bonded Together To Get The Finished Wadding Product. |

| High Light: |

Single Layer 15m/Min Thermal Bonding Machine,Nonwoven Thermal Bonding Machine,Thermal Bonding Machine for Mattress Making |

||

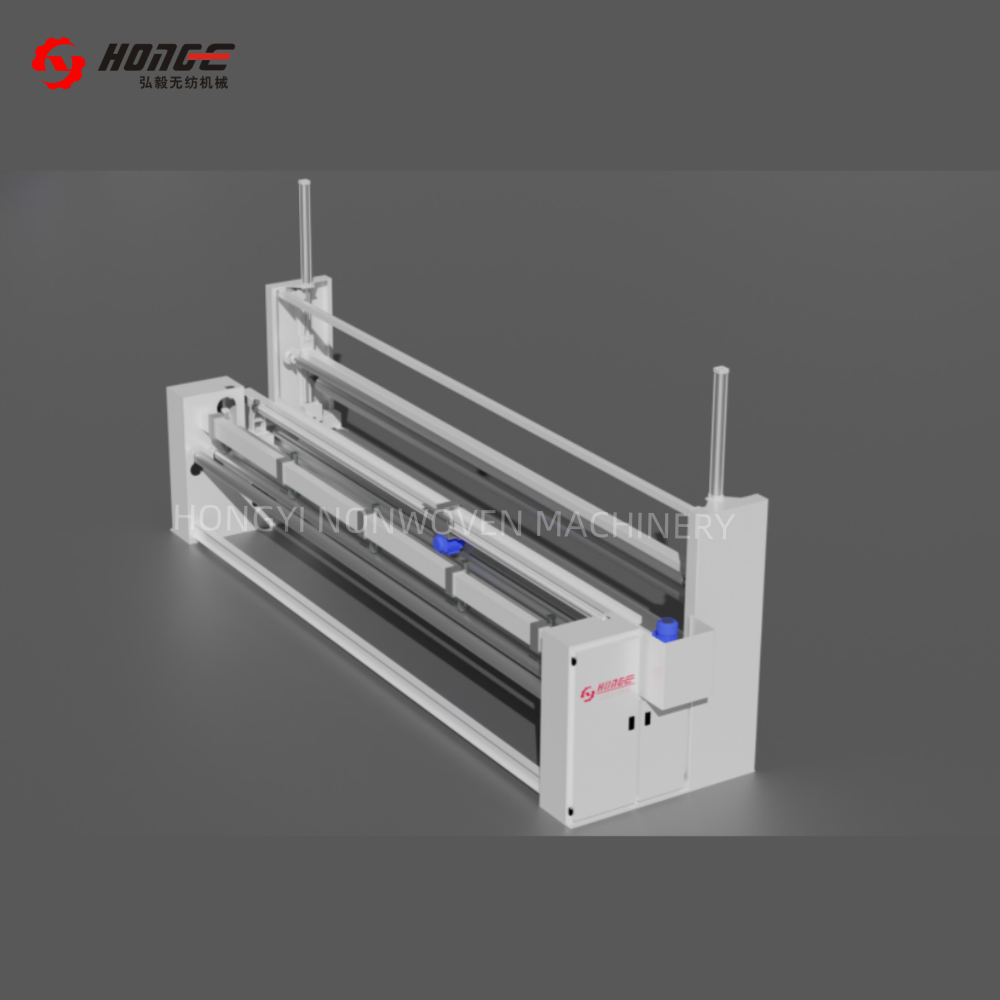

Single Layer Nonwoven mattress making thermal Bonding Machine

Introduction:

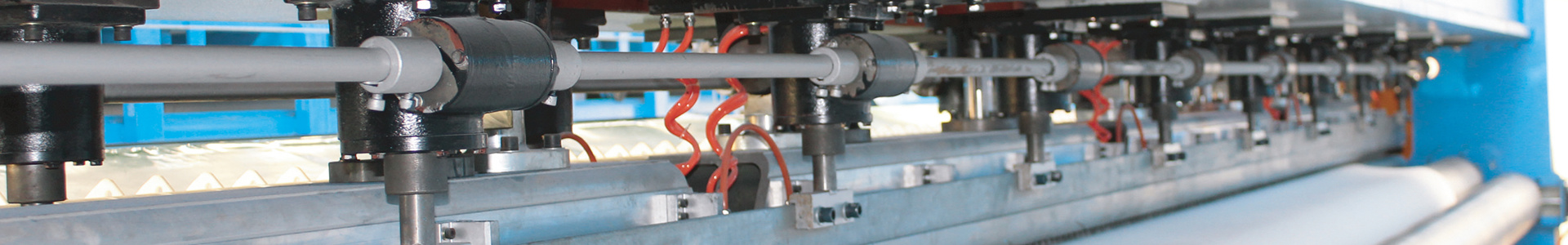

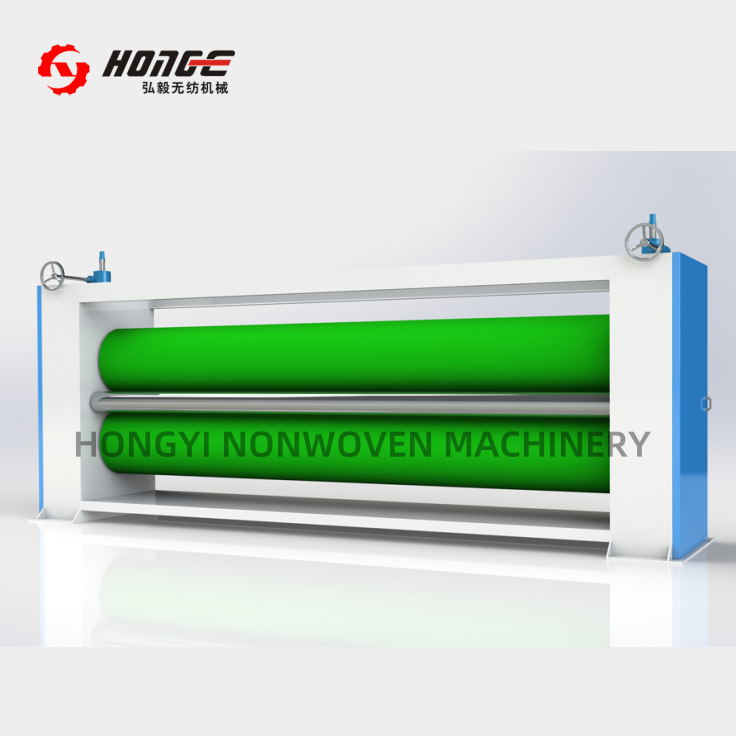

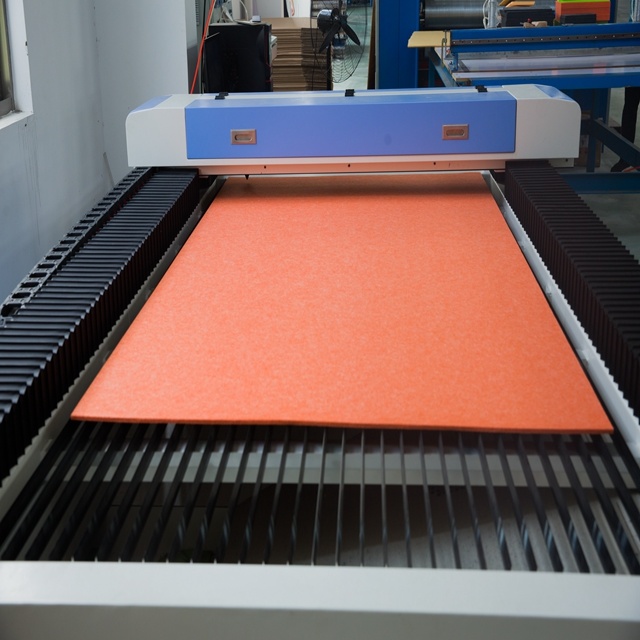

The thermal bonding machine has a perforated- rotating drum, a wire-mesh drum cover layer and a wire-mesh looped conveyor belt. The drum and drum cover are enclosed by a hood with an open section to enable the conveyor belt and the transported web to enter and exit the thermal bonding machine. The nonwoven web enters the machine transported by the conveyor belt, from room temperature, and is then subject to hot air flow, which is at or just above the melting temperature of the sheath fibre material. The web is located such that it is wrapped around the drum, sandwiched between the conveyor belt and the drum cover, first travelling through the machine’s heating zone facilitating the bonding of the contacting fibres, and then it is briefly subject to a cool air flow before leaving the machine. 2–4 The convective hot air flows through the conveyer belt, then through the porous nonwoven web and finally through the drum cover and the perforated drum.

Technical parameters:

- Working width: 2400mm

- Heating chamber length: 7000mm

- Temperature: Max. 220℃

- Working speed: 4-15m/min

- Installed power: 142Kw

- Heating resource: natural gas

- Heating burner: RIELLO from Italy

- Characteristics:

- Three sections, the first two sections for heating and the last section for cooling;

- TEFLON convey belt;

- Automatic tracking system;

- Temperature control by three-district throttle valve;

- Stainless filtration belt assembled at the top to adsorb the fiber from the fan, prevent the fire;

- Multiple-unit pressing rollers are matched at the out part of cooling to control thickness of fabric.

Trade information:

|

Trade terms

|

EXW, FOB, CIF

|

|

Leading time

|

90 days

|

|

HS code

|

8449009000

|

|

Payment terms

|

30% deposit, 70% paid off before loading.

|

|

Warranty

|

12 months

|

|

After-sale service

|

The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition, the buyers should assign a translator, workers, electrical cable (from machines to control panel and from power to control panel), and tools for installation to cooperate with the work.

Installation cost is USD200/Day/engineer and totally installation period is about 30-35 days depending on well cooperation of the buyer. |

Contact us:

Email: admin@hongyiwf.cn/ rainbow@hongyiwf.cn

Tel: +86-512-52860355

Fax: +86-512-52938505

Related Products

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time