Nonwoven Thermal Bonding Oven for Nonwoven wadding production line

Product description

Product Details

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HONGE |

| Certification: | CE/ISO9001 |

| Model Number: | HYHX |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiation |

| Packaging Details: | NUDE AND WOODEN CASE |

| Delivery Time: | 100 DAYS AFTER RECEIVIBF DEPOSITE |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3-5 SET 100DAYS |

Nonwoven Thermal Bonding Oven for Nonwoven wadding production line

Description

| Name: | Nonwoven Wadding Thermal Bonding Machine For Mattress | Key Selling Points:: | Environmental |

|---|---|---|---|

| Power: | 250-415KW | Product Width: | 2.5m-3.2m |

| Work Speed: | 1-15m/min | Voltage: | 220V/380V |

| Heating Method: | Natural Gas, Electricity | Usage: | Melt The Low Melting Point Fiber In Fiber Web And Increase The Tension Of Fiber Web. |

| High Light: |

415KW thermal bonded machine,nonwoven thermal bonded machine,Spunbond meltblown production machine |

||

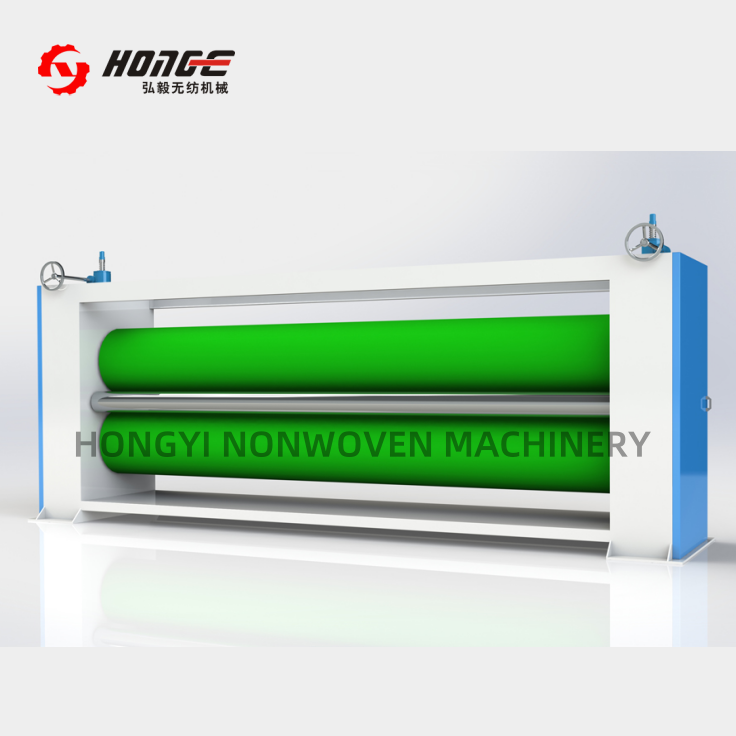

Non Woven thermal Bonding Oven for Non Woven wadding production line

Introduction:

Thermal bonding oven is used for the thermal treatment of thick fiber web from last process, in order to melt the low melting point fiber in fiber web and increase the tension of the fiber web. Non-glue cotton does not contain glue and thus more environmental.

Non-glue cotton is also more soft than acupuncture cotton and can be made for thicker cotton products. Thus non-glue cotton is generally used for high end products, such as high end mattress, seat cushion, back cushion, etc. Thermal bonding oven for non-glue cotton with natural gas as the heating material is displayed below. We can also offer themal bonding oven for non-glue cotton with other heating materials like electric heating, coal, steam boiler, etc. So that you can choose most suitable drying oven according to your local energy cost.

It utilizes a servo motor and servo controller system or inverter with web storage and profiling function to keep the web thickness uniformly

Servo motor central controlling system and PLC touch screen interface. this provides high-quality web controlled by computer to ensure quality as well as speed

- Bedding furniture, high-quality mattress, wadding

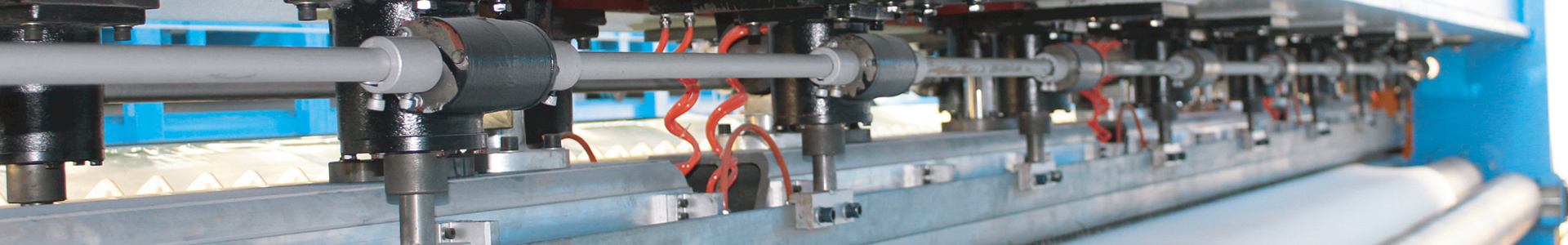

- double layer chain board and Teflon coated, upper layer with independent lifting

- two high-pressure circulation blowers , supreme insulation system to save energy

Application for soft wadding production line:

|

Raw material |

polyester fiber, waste fiber, low melt fiber, etc. |

|

Trim width |

2500mm |

|

Weight range |

400g/m2-4000g/m2 |

|

Production capacity |

400kg/h |

Trade information

|

Trade terms

|

EXW, FOB, CIF

|

|

Leading time

|

90 days

|

|

HS code

|

84490090

|

|

Payment terms

|

30% deposit, 70% paid off before loading.

|

|

Warranty

|

12 months

|

|

After-sale service

|

The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition, the buyers should assign a translator, workers, electrical cable (from machines to control panel and from power to control panel), and tools for installation to cooperate with the work.

Installation cost is USD200/Day/engineer and totally installation period is about 30-35 days depending on well cooperation of the buyer. |

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time