300kg/H Thermal Bonding Machine Non Woven Fabric Production Line

Product description

Product Details

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HongYi |

| Certification: | CE/ISO |

| Model Number: | 2900 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiation |

| Packaging Details: | NUDE AND WOODEN CASE |

| Delivery Time: | 15DAYS AFTER RECEIVIBF DEPOSITE |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 SER 7DAYS |

300kg/H Thermal Bonding Machine Non Woven Fabric Production Line

Description

| Production Capacity:: | 80-300kg/h | Certification: | CE |

|---|---|---|---|

| Name: | Nonwoven Wadding Thermal Bonding Machine For Mattress | Product Width: | 2.5m-3.2m |

| Work Speed: | 1-15m/min | Voltage: | 220V/380V |

| High Light: |

300kg/h Thermal Bonding Machine,ISO Thermal Bonding Machine,3.2m non woven fabric production line |

||

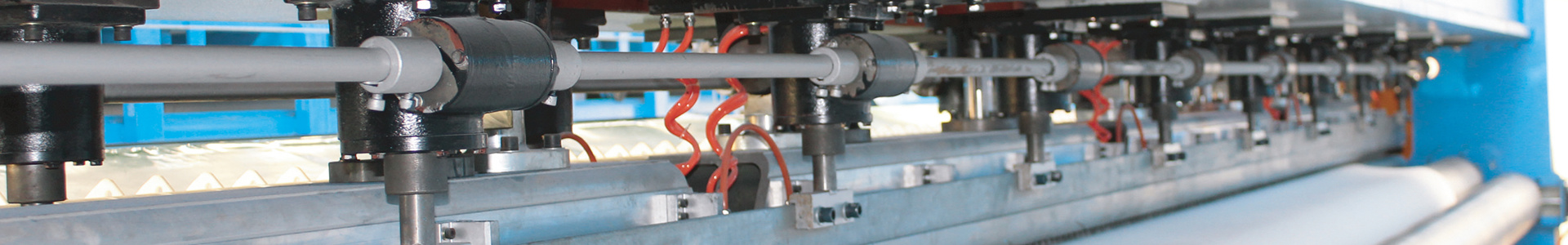

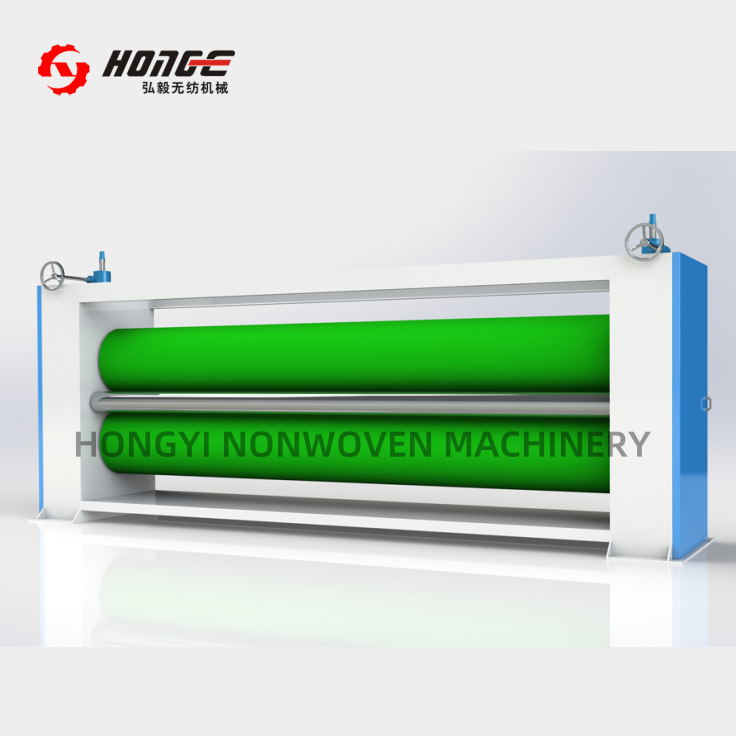

Thermal Bonding Quilt Wadding Mattress Making Machine

| Nonwoven machine wadding production line, Thermal bonding machine, Wadding machine | |

| Working width | 6800mm(adjustable from 2500-9800mm) |

| Max frequency | ≤600s/min |

| Stroke | 55mm(adjustable for customers' requirements) |

| Needleing type | up-down/down-up(adjustable for customers' requirements) |

| Delivery speed | 1-8m/min |

| Needle density | 2500-3500n/m(adjustable for customers' requirements) |

| Needle fix beam | Alumimum Alloy |

| Guiding Pipe | Copper sheating |

| Needle boards | The material is Epoxy resin or Alimimum Alloy, drilled with computer NC driller (hole 1.83m), so that certain the distance between the holes and the vertical between the hole and needle plate. The method of placing needles is decided by the requirement of the products. Fixing by screw. |

| Steel plate | The supporting board and stripper board are made of carbon steel of 12mm, hole 4.2mm, with chromium-plated surface, and polishing. Supporting net board and stripper board adopt electric for lift and down. |

| Frame | Machine frame is welded by carbon steel, with different thickness between 30mm-16mm,annealed under high temperature to eliminate internal stress. |

| Main components | The frame made from high quality metal plate,aluminum alloy beam and magnesium aluminum alloy/PU combined needle board. |

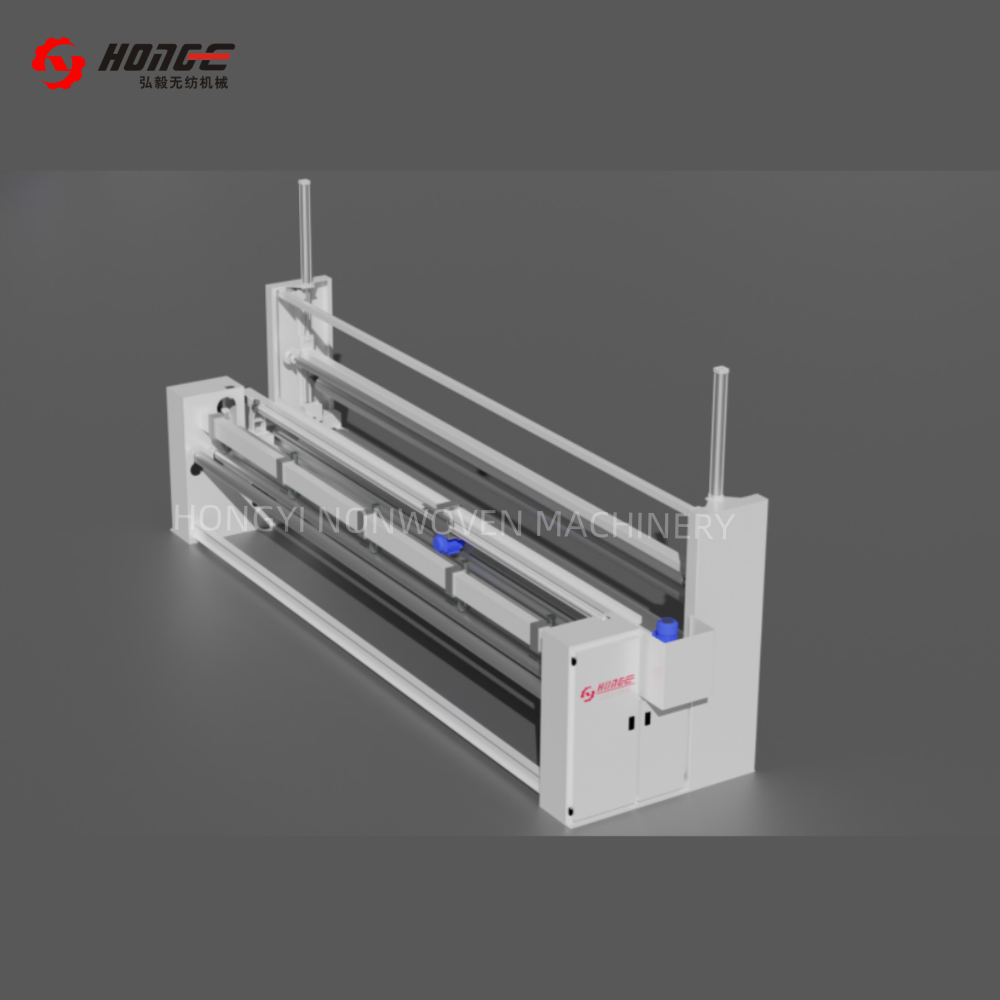

It utilizes a servo motor and servo controller system or inverter with web storage and profiling function to keep the web thickness uniformly

Servo motor central controlling system and PLC touch screen interface. this provides high-quality web controlled by computer to ensure quality as well as speed

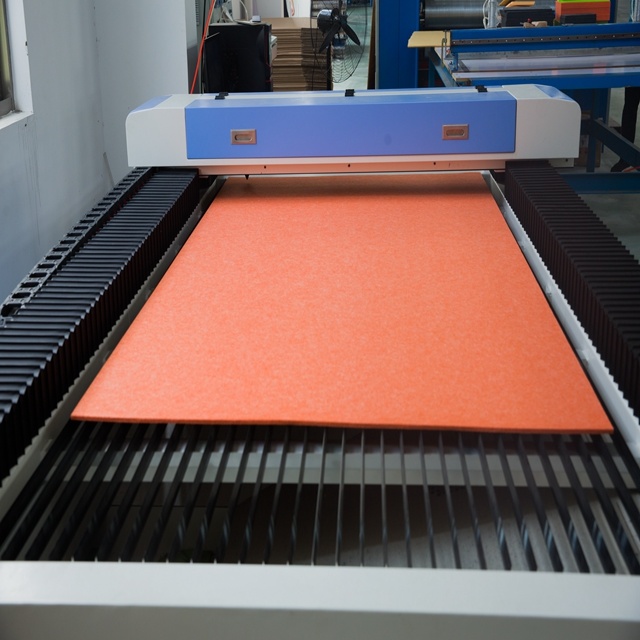

- Bedding furniture, high-quality mattress, wadding

- double layer chain board and Teflon coated, upper layer with independent lifting

- two high-pressure circulation blowers , supreme insulation system to save energy

|

Raw material |

polyester fiber, waste fiber, low melt fiber, etc. |

|

Trim width |

2500mm |

|

Weight range |

400g/m2-4000g/m2 |

|

Production capacity |

1000kg/h |

|

Trade term |

FOB Shanghai |

|

Payment term |

30% T/T advance, 70% paid off before delivery. |

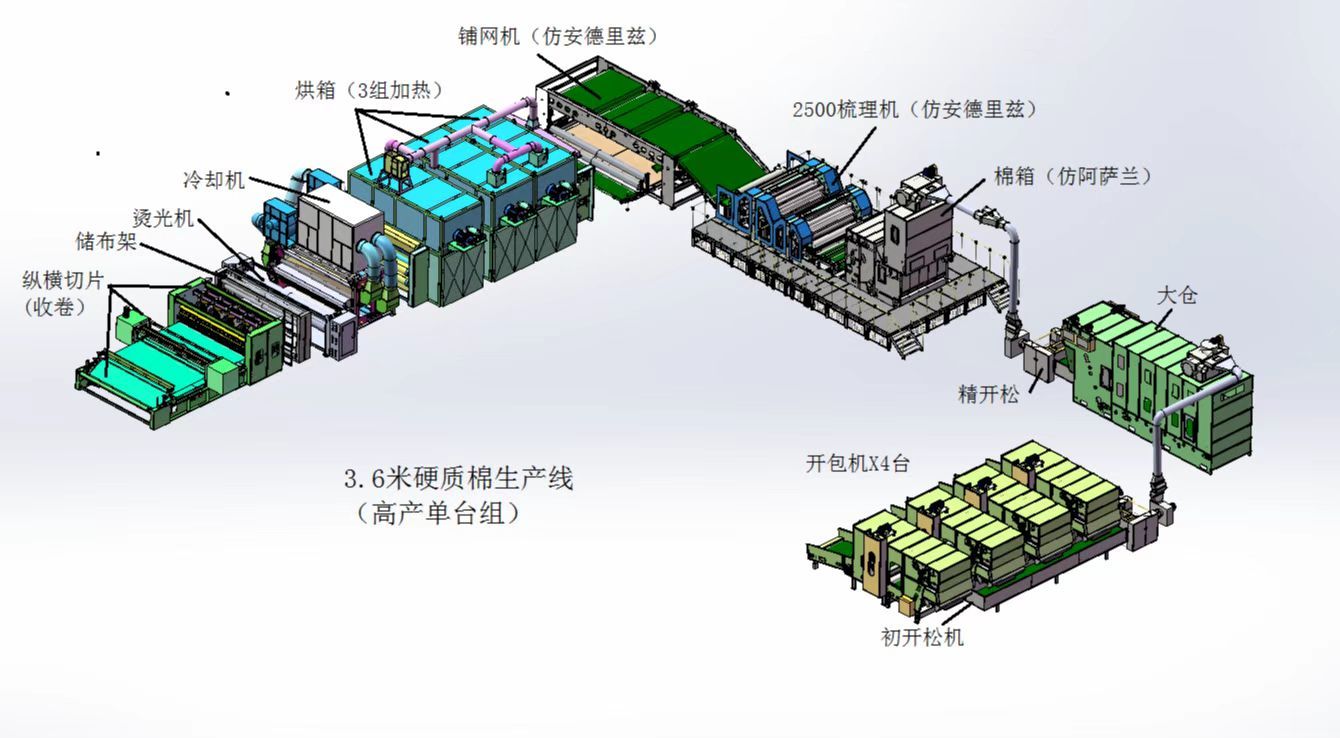

technical parameter

- machine width: 2600-3800mm

- chamber length: 4800-6000mm

- heating method: circulated hot oil direct burning

- Capacity :1000KG/H

|

Trade terms

|

EXW, FOB, CIF

|

|

Leading time

|

90 days

|

|

HS code

|

84490090

|

|

Payment terms

|

30% deposit, 70% paid off before loading.

|

|

Warranty

|

12 months

|

|

After-sale service

|

The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition, the buyers should assign a translator, workers, electrical cable (from machines to control panel and from power to control panel), and tools for installation to cooperate with the work.

Installation cost is USD200/Day/engineer and totally installation period is about 30-35 days depending on well cooperation of the buyer. |

Related Products

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time