Proportional Fiber Mixing Machine For Mixing Different Materials

Product description

Product Details

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | HONGYI |

| Certification: | ISO9001, CE |

| Model Number: | HYDC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2sets |

|---|---|

| Price: | negotitable |

| Packaging Details: | PE film |

| Delivery Time: | 30 days. |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets per month. |

Proportional Fiber Mixing Machine For Mixing Different Materials

Description

| Core Components:: | PLC, Bearing, Motor | Working Width: | 1400mm-2500mm |

|---|---|---|---|

| Raw Material: | Polyester Fiber, Wool, Cotton, Etc. | Color: | Customized |

| Capacity: | 300kg/h | Volume: | 16m3-30m3 |

| High Light: |

1400mm Fiber Mixing Machine,Proportional Fiber Mixing Machine,OEM nonwoven fabric production line |

||

Proportional Mixing Machine Price For Mixing Different Materials

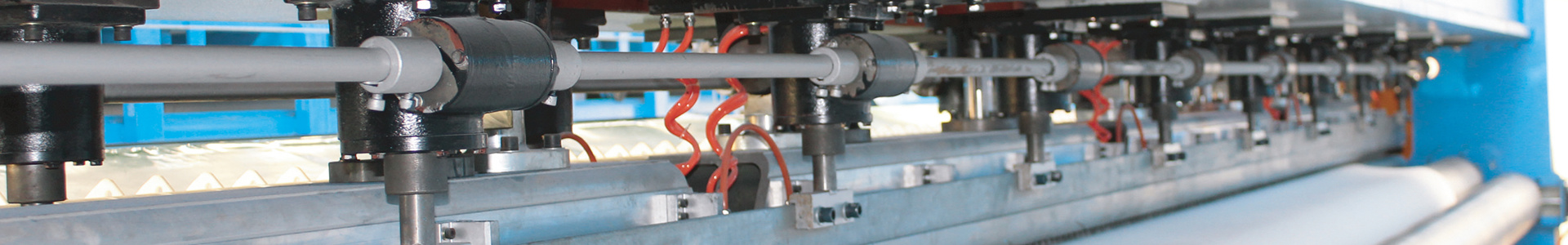

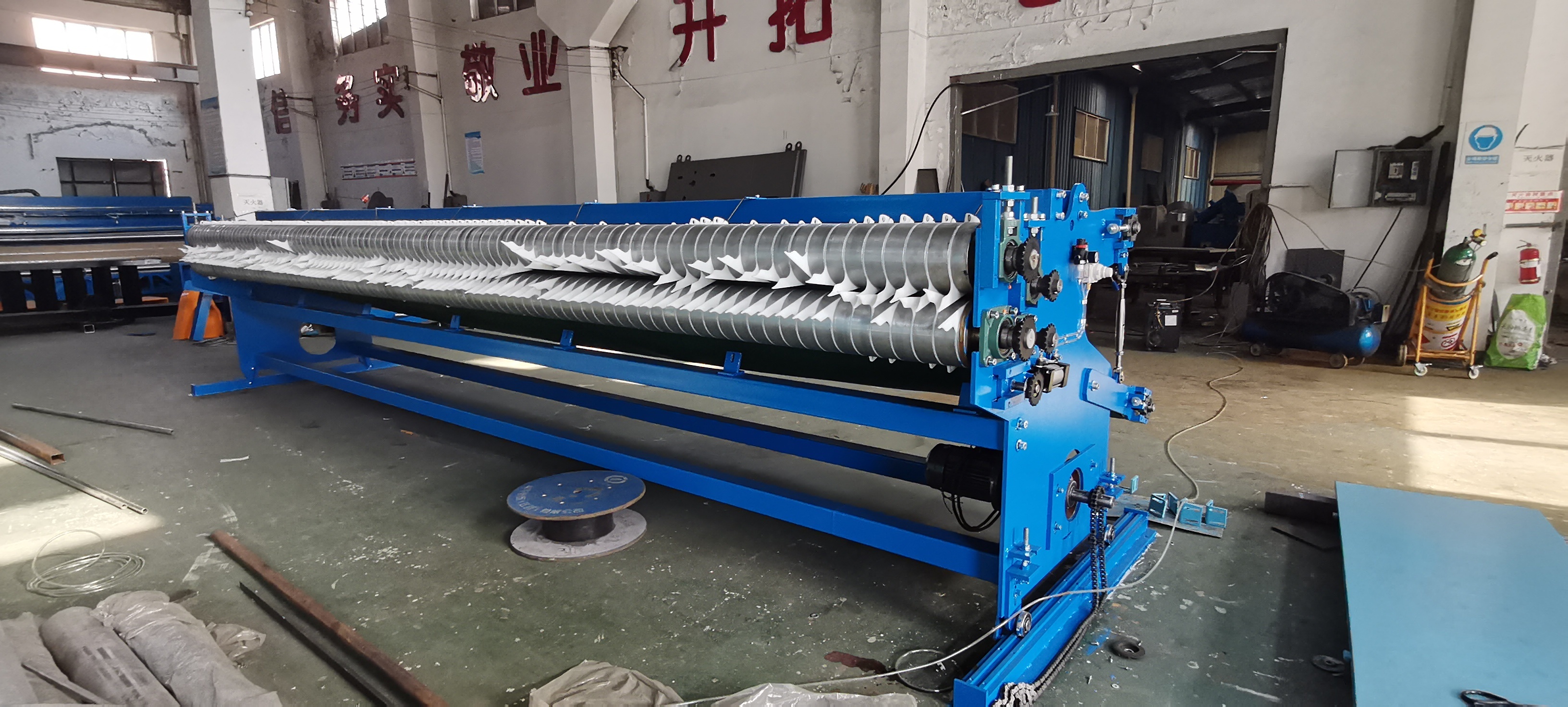

1. This machine is designing for mix two kinds of different materials proportionally.

2. Automatically adjust the ratio of the two materials, then mix them together, in order to get desired effect.

3. Usually work with two filling machines.

4. With automatical weighting system.

Features:

1. Photoelectric control during the production process.

2. Fiber density spreads even.

3. The stripper and evener roller are in the independent transmission. This will be with high dependability, easy adjustment and maintenance.

4. The spike lattice with the machine behind control the feeding by Photoelectric to make the blending evener.

Technical parameters:

| Working width | 1400mm, 1700mm, 2500mm |

| Storage volume | 16m3-30m3 |

| Capacity | 300kg/h, 500kg/h, 800kg/h |

| Installed power | 8.8Kw |

Trade information:

| Trade terms | FOB, CNF, or CIF |

| Lead time | 90 days after deposit. |

| Payment terms | 30% advance payment, 70% paid off before delivery. |

| Warranty | twelve (12) months after mechanical and electrical commissioning. |

| After-sale service |

The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition the buyers should assign translator, workers, electrical cable (from machines to control panel and from power to control panel) and tools for installation to cooperate with the work. Installation cost is USD180/Day/engineer and totally installation period is about 30-40 days depending on well cooperation of the buyer. |

Related Products

Product

Contacts

Phone: 86-512-52860355

Tel: 86-15262513303 (whatsapp)

Fax: 86-512-52860355

Website: www.hongewf.com

Email: admin@hongyiwf.cn

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

Phone:86-512-52860355

Tel:86-15262513303

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:86-15262513303

Email: admin@hongyiwf.cn

We will give you feedback in time