Nonwoven Production Machine Fiber Mixing Machine Big Chamber Blender HONGE 2024 New Type HYDC-250 Big Chamber Blender /Non Woven Fiber Mixing Machine

Product description

Product Details

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | HONGE |

| Certification: | ISO9001, CE |

| Model Number: | HYDC-250 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1sets |

|---|---|

| Price: | Negotitable |

| Packaging Details: | Wooden package or PE film or naked |

| Delivery Time: | 80 days. |

| Payment Terms: | L/C, T/T |

HONGE 2024 New Type HYDC-250 Big Chamber Blender /Non Woven Fiber Mixing Machine

Description

| Working Width: | 2500mm | Control: | PLC |

|---|---|---|---|

| Raw Material: | Polyester Fiber, Wool, Cotton, Waste fiberEtc. | Color: | Customized |

| Capacity: | Max.650kg/h | Warranty: | 1 Year |

| Volume: | 35m3 | ||

| High Light: |

2500mm Fiber Mixing Machine,HONGYI Fiber Mixing Machine,OEM nonwoven making machine |

||

HONGE 2024 New Type HYDC-250 Big Chamber Blender /Non Woven Fiber Mixing Machine

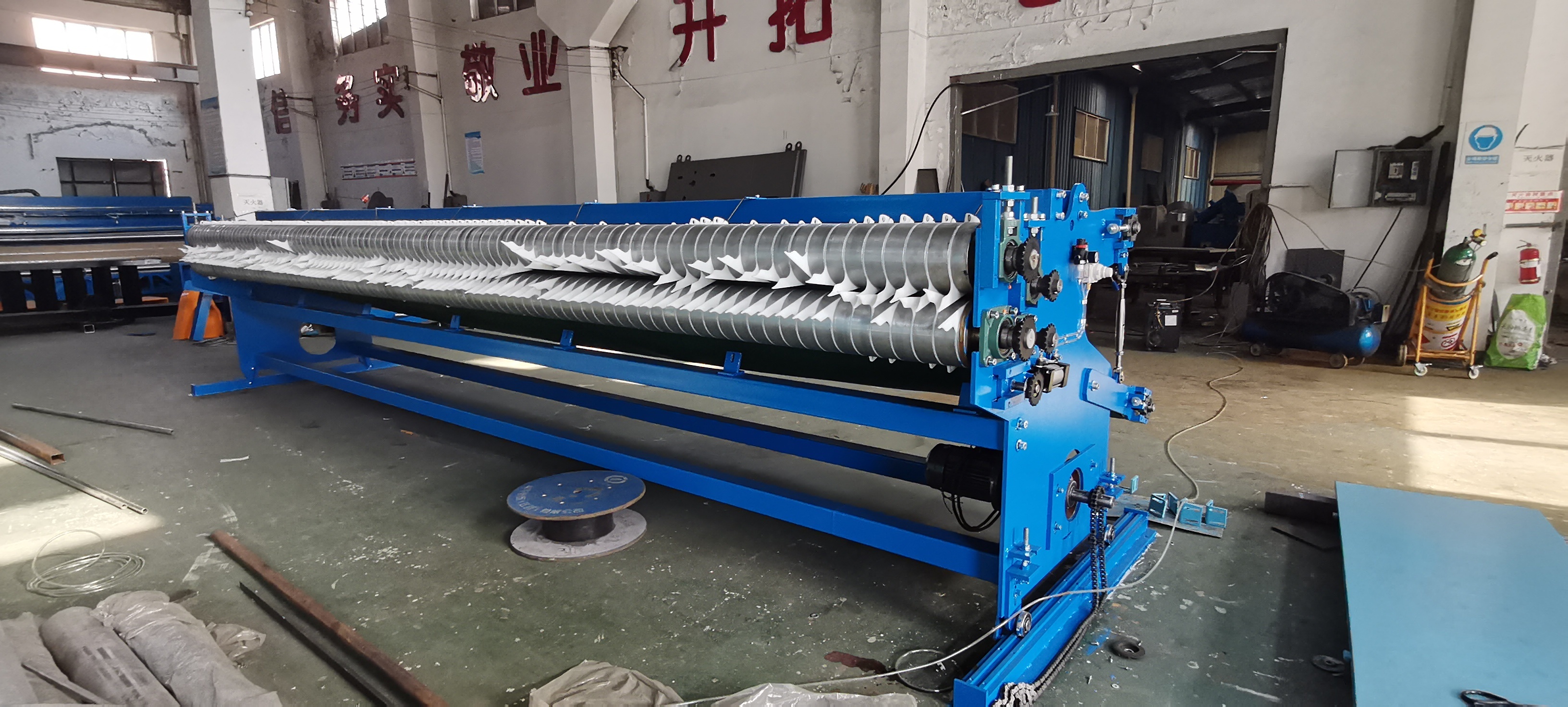

This machine is used to mix and store the opened fiber in a large volume to achieve continuous automated production.

1.Technical data:

working width: 2500mm

Volume of fiber storage: 35m3

Production capacity: max. 1200kg/hr.

Installed power: 24.37kw

- Structure:

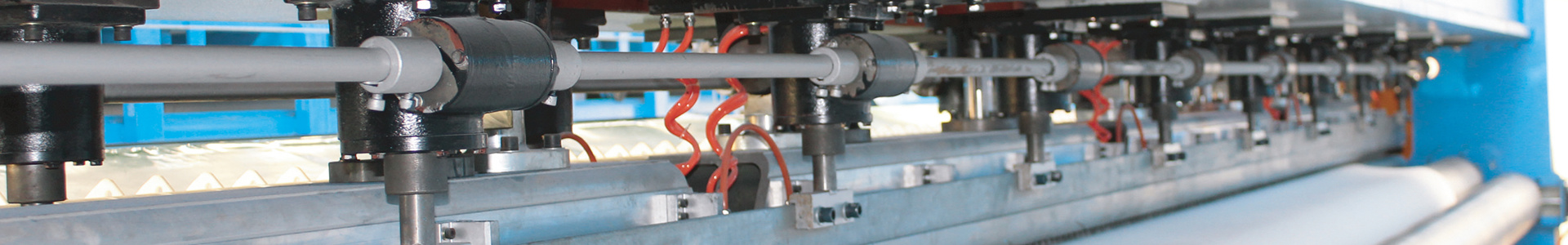

- The machine is composed of conveying fan, feeding pipe, roller beater, mixing tank, discharging channel, and electrical control.

- Machine frame is several wall-boards welded by Q235-A armor plate, combined by bolts.

- The observation window is equipped with photoelectric sensor, which controls the material difference in the warehouse and matches with the front and rear channels.

- The cotton conveying fan feeds the raw material into each cotton bin through the cotton conveying pipe and trough. The lower part of the cotton bin is equipped with a clamping roller and a six-wing toothed steel beater. The bottom outlet is connected with the cotton conveying fan.

- The spiked lattice is made of high quality wood with canvas interlining and surrounded with angle steel for supporting.

- Equipped with three condensers on the top for dust removing.

- A transferring fan will be matched at the output of the blending connect to the vibrating feeder.

Technical parameters:

| Working width | 2500mm |

| Storage volume | 35m3 |

| Capacity | 1200kg/h |

| Installed power | 24.37kw |

Trade information:

| Trade terms | FOB, CIF |

| Lead time | 90 days after deposit. |

| Payment terms | 30% advance payment, 70% paid off before delivery. |

| Warranty | twelve (12) months after mechanical and electrical commissioning. |

| After-sale service |

The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition the buyers should assign translator, workers, electrical cable (from machines to control panel and from power to control panel) and tools for installation to cooperate with the work. Installation cost is USD180/Day/engineer and totally installation period is about 30-40 days depending on well cooperation of the buyer. |

Big chamber blender

Fiber mixing machine

HONGE

Non woven production line

HONGYI

automotive interior

geotextile

GCL

filtration

carpet

felt

mattress

bale opener

opening machine

vibrating feeder

carding machine

cross lapper

oven

Related Products

Product

Contacts

Phone: 86-512-52860355

Tel: 86-15262513303 (whatsapp)

Fax: 86-512-52860355

Website: www.hongewf.com

Email: admin@hongyiwf.cn

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

Phone:86-512-52860355

Tel:86-15262513303

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:86-15262513303

Email: admin@hongyiwf.cn

We will give you feedback in time