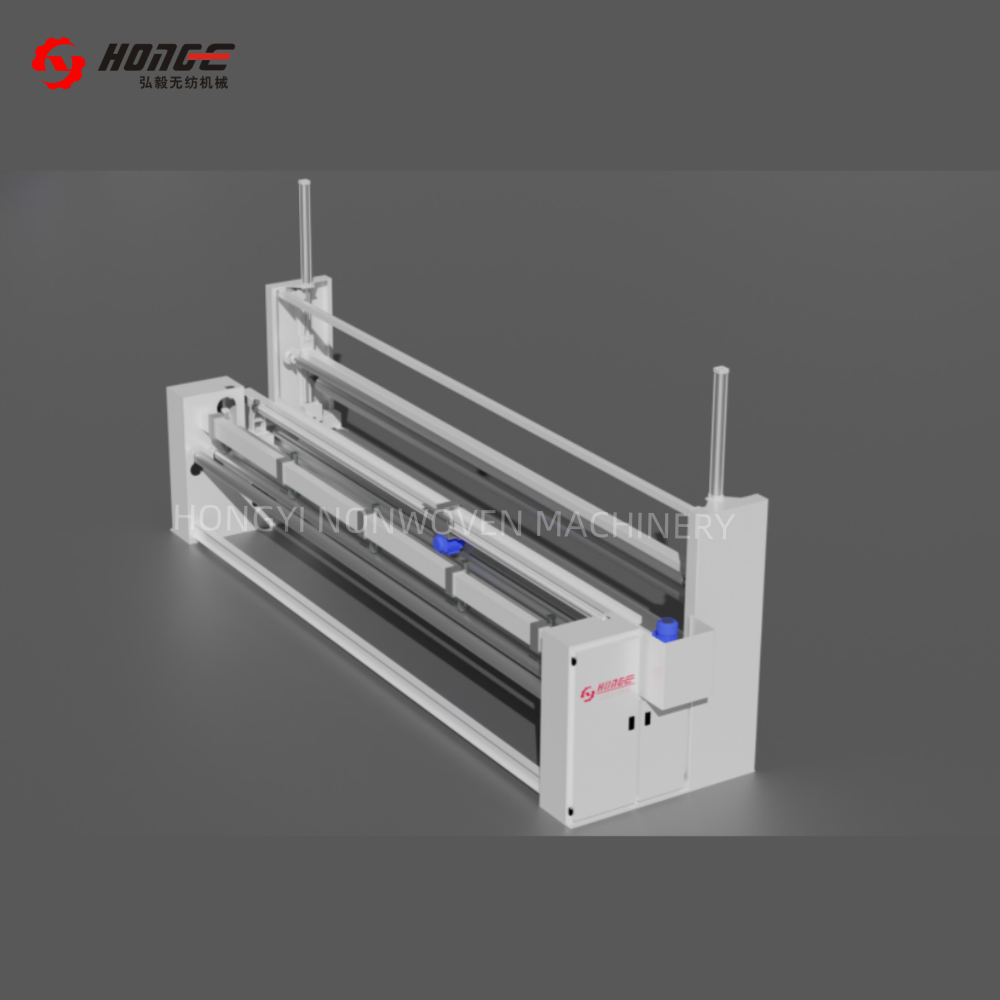

150m/Min PP Spunbond Nonwoven Machine Man Machine Interface

Product description

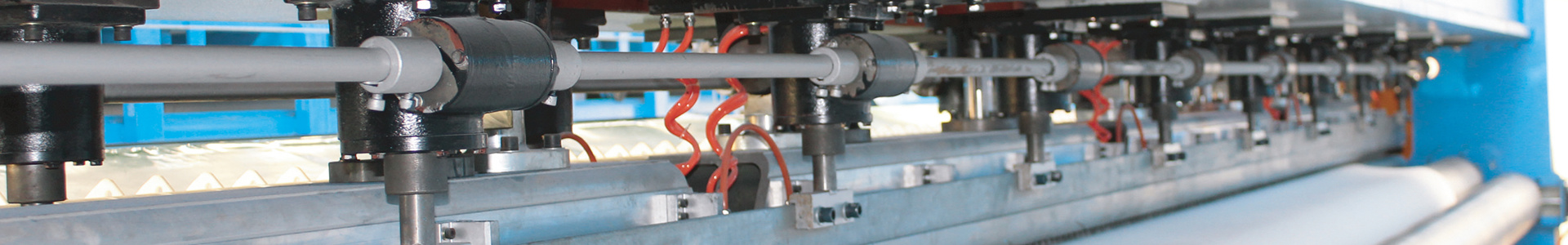

Product Details

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | Honge |

| Certification: | CE ISO |

Payment & Shipping Terms:

| Price: | $350,000.00/Sets >=1 Sets |

|---|---|

| Packaging Details: | Nude or wooden case |

150m/Min PP Spunbond Nonwoven Machine Man Machine Interface

Description

| Weight: | Weight | Voltage: | 220V/380V |

|---|---|---|---|

| Local Service Location: | None | Showroom Location: | None |

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Not Available |

| Warranty Of Core Components: | 1 Year | Core Components: | PLC, Engine, Motor |

| Condition: | New | Automatic Grade: | Automatic |

| Warranty: | 1 Year | After-sales Service Provided: | Video Technical Support, Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service |

| Key Selling Points: | Automatic | Product Name: | PP Spunbond Nonwoven Fabric Machine |

| Raw Material: | PP Chips | Machine Type: | S, SS, SSS, SMS |

| Width: | 1600-3200mm | Speed: | 150m/min |

| Product Weight: | 10-150g/m2 | Technology: | Spundond |

| Application: | Shopping Bags, Baby Diaper, Furniture, Etc. | Control Panel: | Man-machine Interface (touch Screen) |

| After-sales Service: | One Year Gurantee | Port: | SHANGHAI |

| High Light: |

PP spunbond nonwoven machine,150m/min PP spunbond nonwoven machine,PP spunbond non woven production line |

||

PP spunbond non woven production line

Applications:

This production line is especially applicable for producing soft wadding(padding), fiberfill products using synthetic fiber and chemical binder.

Technical preference:

| Working width: | 2300mm- 4000mm |

| 100kg/h - 300kg/h | |

| Available products: | 80gsm - 500gsm |

| Available raw material: | PP, PET, etc |

Our quality and warranty :

1. Selected component suppliers: SIEMENS, INA, TWB and etc.

2. TQM for each production procedure

3. Turnkey project : installation and commissioning

4. Spare parts in one-stop solution

5. One year warranty period

| item | value |

| Core Components | PLC, Engine, Motor |

| Automatic Grade | Automatic |

| Product name | PP Spunbond Nonwoven Fabric Machine |

| Raw material | PP Chips |

| Machine Type | S, SS, SSS, SMS |

| Width | 1600-3200mm |

| Speed | 150m/min |

| Product weight | 10-150g/m2 |

Advantages

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2. High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our machines' actual production output

is10%-20% higher than the same model in the market;

3. Simple installation:

The equipment is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time.

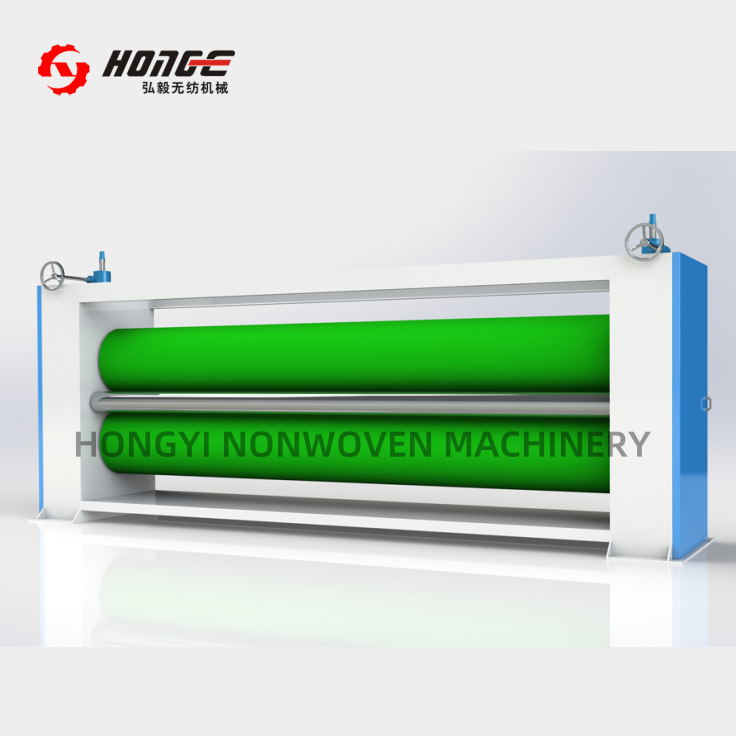

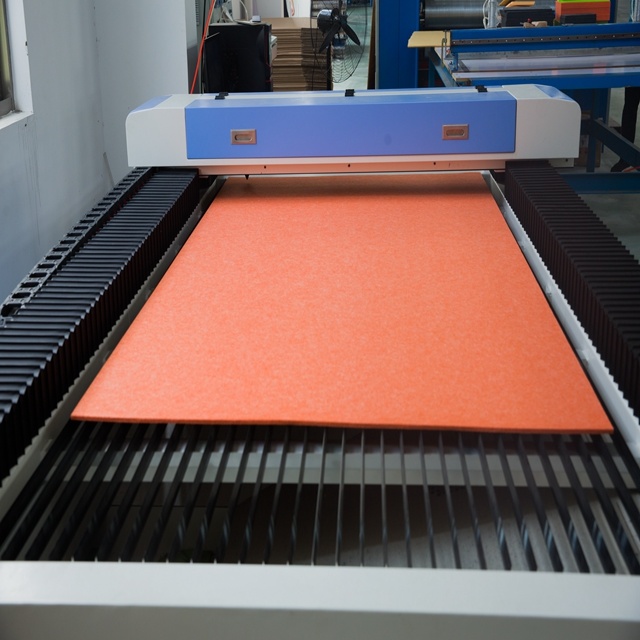

Related Products

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time