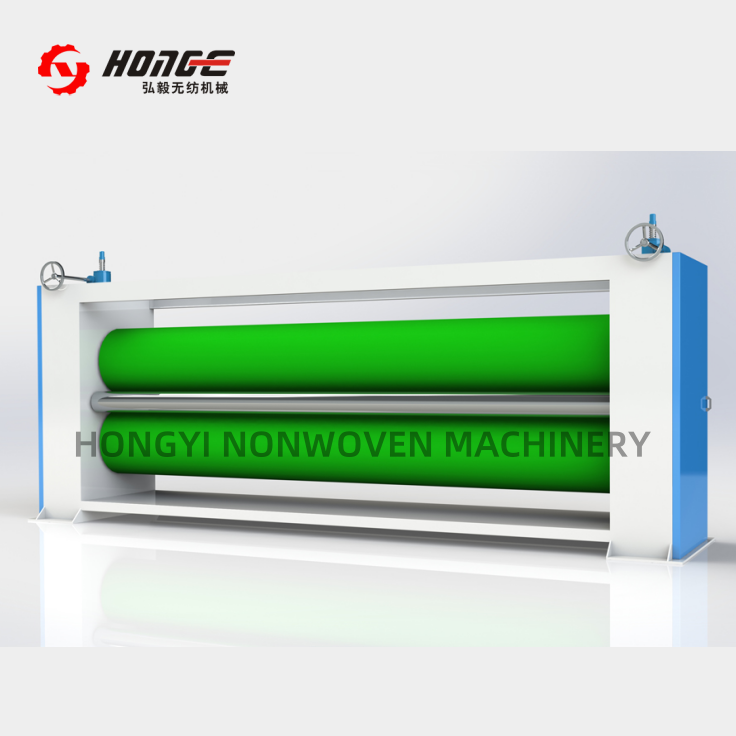

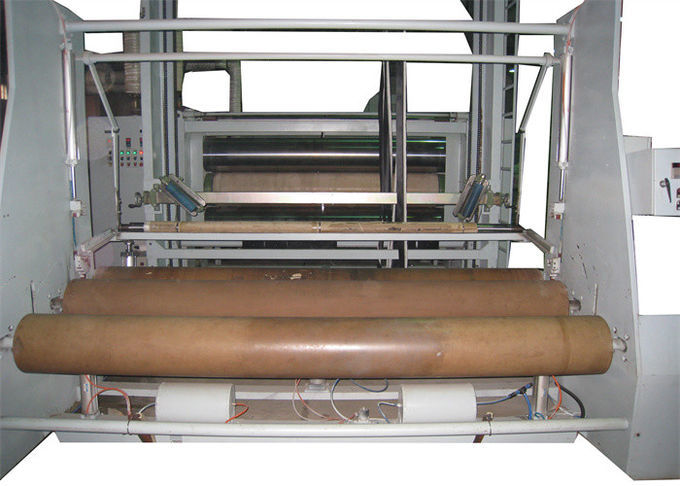

3KW Non Woven Roll To Sheet Cutting Machine PLC Touch Screen Control

Product description

Product Details

Product Details:

| Place of Origin: | Jiangsu, China |

|---|---|

| Brand Name: | HongYi |

| Certification: | CE/ ISO9001 |

Payment & Shipping Terms:

| Price: | $25,000.00/Sets >=1 Sets |

|---|---|

| Packaging Details: | wooden case or naked |

| Supply Ability: | 1 Set/Sets per Day |

3KW Non Woven Roll To Sheet Cutting Machine PLC Touch Screen Control

Description

| Features: | Automatic | Cloth Width:: | 1.7m |

|---|---|---|---|

| Max. Workable Width:: | Max. Workable Width: | Local Service Location: | None |

| Showroom Location: | None | Video Outgoing-inspection: | Provided |

| Machinery Test Report: | Not Available | Marketing Type: | Ordinary Product |

| Warranty Of Core Components: | 1 Year | Core Components: | Bearing |

| Condition: | New | Application: | Fabric |

| Automatic Grade: | Automatic | Production Capacity: | 100% |

| Voltage: | 380V/220V | Power: | 3kw |

| Dimension(L*W*H): | 2270mm*1400mm*2580mm | Weight: | 100kg |

| Warranty: | 1 Year | After-sales Service Provided: | Free Spare Parts, Video Technical Support, Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Engineers Available To Service Machinery Overseas |

| Product Name: | Winding And Cutting Machine | Cutting Power: | 5kw |

| Material Capabilities: | Soft Wadding And Stiff Wadding Products | Working Width: | 2m-9m |

| Working Speed: | 1-15m/min | Cutting Type: | Cross Cutter And Vertical Cutter |

| Safety Device: | Pre-alarming Bell | Usage: | To Coil The Soft Wadding In Rolls Or Cut Stiff Wadding Into Sheets. |

| Control System: | PLC&touch Screen | Port: | Shanghai |

| High Light: |

3KW non woven roll to sheet cutting machine,CE non woven roll to sheet cutting machine,380V non woven fabric machinery |

||

Non-Woven Fabric Roll Strip Binding Cutting Slitting Rewinding Machine Ultrasonic Sewing Machine

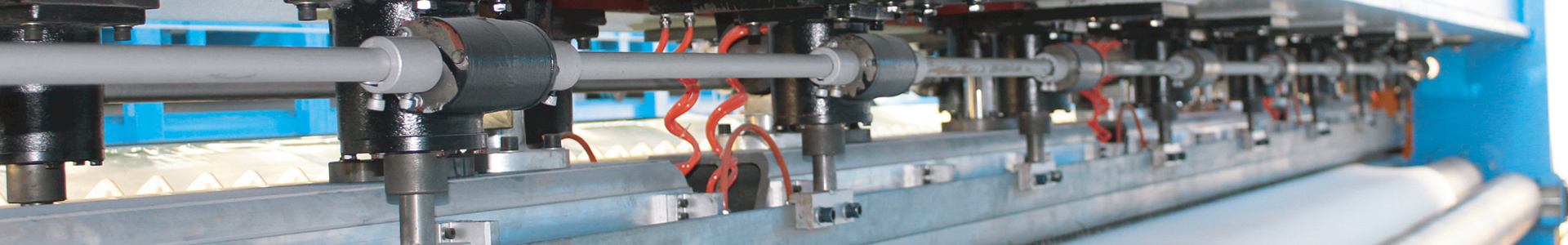

1. round knife, plate kapoor (cloth) motor adopts frequency control, can be arbitrary speed and positive &negative switching control, never stick knife

2. equipped with automatic sharpening system, blade don't remove, can be intermittent grinding, the machine adopts diamond grinding wheel, grinding time and cost savings;With aspiration filling quantity, cleaning cloth and a knife cut.Keep track and cloth clean.

3. imported PLC programmable controller (commonly known as microcomputer module) control cutting, automatic cutting, can be directly set a variety of cutting width and quantity, improving the precision of cutting binding.Save automatically save electricity parameters, can be arbitrary calls;The size is accurate.

4. import ball slide rail, parallel advance cutting width, not easy to wear and tear, with precision ball screw and slide rail, greatly control precision, the accuracy of 0.1 mm.Reduce the defective rate, achieve high quality cut.

5. interface using Chinese LCD display, visual man-machine interface to save time, simple operation, can be directly set a variety of cutting width and quantity, can choose according to need manual/automatic conversion function, direct labor per capita can be used.

6. using triangular vertical bracket design, feeding and discharging only one step to complete, more convenient.

7. the cutting machine set has a stop button, if there are abnormal circuit or operation, just point the stop button, and safe operation.

|

Working width

|

1500-8000mm

|

|

Working speed

|

1-15m/min

|

|

Power

|

2.2-7.5kw

|

|

Suitable product

|

Needle punched and thermal bonded product

|

|

Motor brand

|

Siemens Beide made in Suzhou

|

|

Warranty

|

1 year for main parts

|

|

After-sale service

|

Online technical service, free spare parts

|

|

Payment terms

|

30% as advance payment by T/T

70% as balance paid off before delivery.

|

|

Lead time

|

90 working days after 30% advance payment.

|

|

Package

|

Naked or wooden case

|

|

HS CODE

|

84490090

|

|

Warranty

|

The Seller gives a mechanical warranty for all machine parts except from the wearing parts and the problem caused by wrong operation and other man-made factors; the respective warranty period shall be twelve (12) months after mechanical and electrical commissioning.

|

|

Installation and commissioning

|

The installation and start-up will be carried out under the supervision of the Seller’s technicians if the Buyer requests. The Buyer is responsible for providing the necessary number of skilled mechanics, helpers and electrician to assist the whole installation and start-up. The Buyer is in charge of providing round-trip air tickets, appropriate local accommodation, meals, and local transportation for the technicians. The Buyer must assign qualified interpreter during the whole installation, start-up and training. Service cost

for installation, start-up and training is USD180 per engineer per day. |

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time