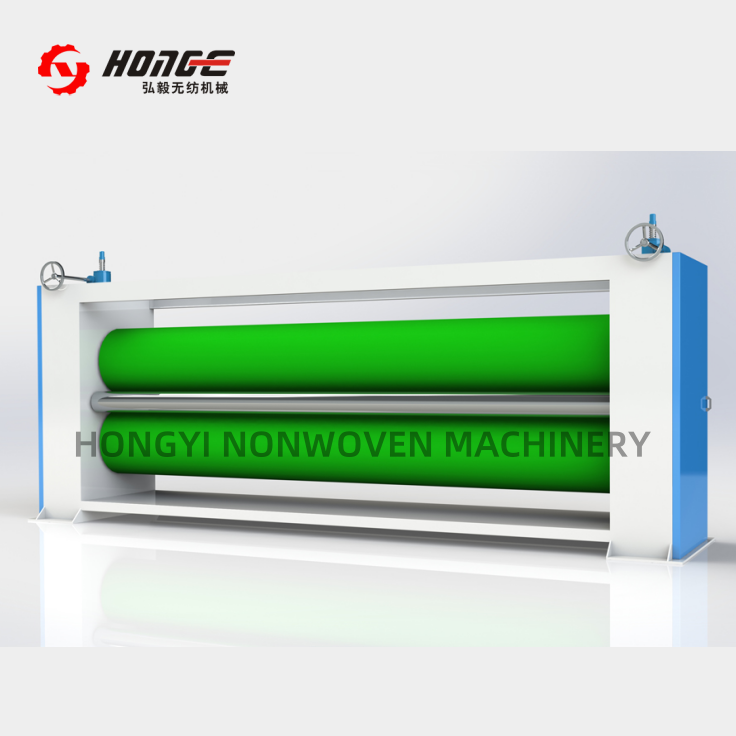

70m/Min Nonwoven Cross Lapping Machine

Product description

Product Details

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HongYi |

| Certification: | CE /ISO9001 |

| Model Number: | HYPW |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | negotiation |

| Packaging Details: | NUDE OR WOODEN CASE |

| Delivery Time: | 7DAYS AFTER RECEIVING THE PAYMENT |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 LINE 120 DAYS |

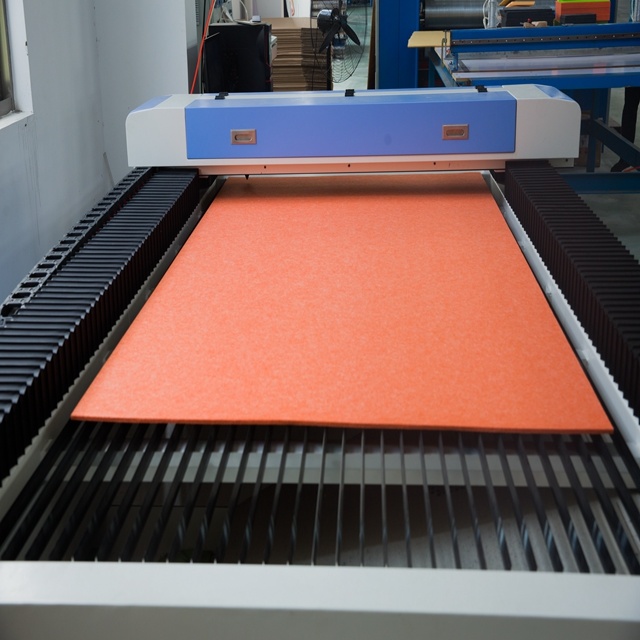

70m/Min Nonwoven Cross Lapping Machine

Description

| Product Width: | 6500mm | Product Weight: | 100~1000g/m2 |

|---|---|---|---|

| Production Capacity: | 500kg/h | Electric Power Supply Required: | 380V 50HZ(Can Be Changed) |

| Lapping speed | 1-70m/min | Output speed | 1~10m/min |

| High Light: |

CE cross lapping machine,70m/Min cross lapping machine,OEM non woven fabric machinery |

||

Factory direct Nonwoven cross lapper machine

To fold and pave the mesh after carding evenly into certain width and thickness,then transfer it to next procedure after pressurization. All paving aprons are driven separately for easy adjustment.The reciprocal commutation is controlled by frequency conversion and the rall is proof against leaking.

Characteristics:

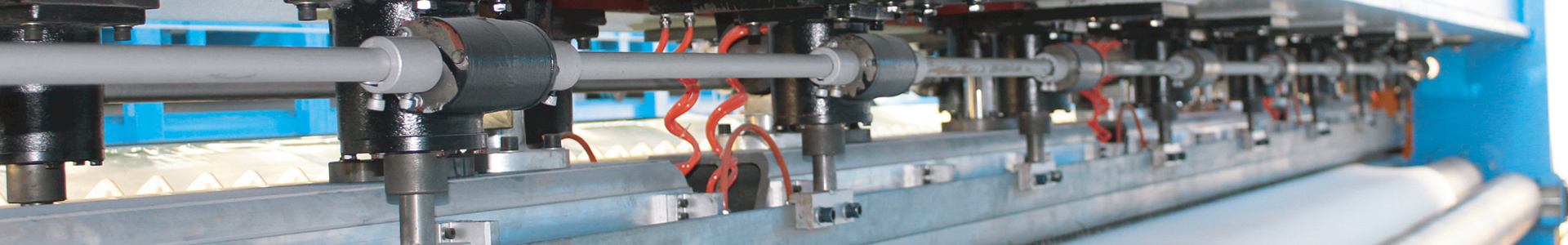

a. Machine frame is 8mm thickness armor plate assembled with brace.

b. Anti-static PVC lattices are for transferring, cross lapping and compensating. Bottom lattice is wooden lattice.

c. Each lattice driving roller is seamless steel, and specially strengthened at the ends of axletree.

d. Cross lapping and Reciprocating is subsection controlled accurately.

e. Reciprocating adopt synchronous belt for drive.

f. Double belt pressing roller lattice is equipped at the output of the cross lapper.

Specifications of the machine for pp nonwoven fabric mattress & felt production line

| Name | machine for pp nonwoven fabric mattress & felt production line |

| Product width | 6500mm |

| Product weight | 100~1000g/m2 |

| Production capacity | 30~40T/d |

| Electric power supply required | 380V 50HZ(Can be changed) |

Pre-Sales Service

*Inquiry and consulting support

*Sample testing support

*View our factory

After-Sales Service

* Training how to install the machine , training how to use the machine

* Engineers available to service machinery overseas

* Warranty :12 months

* Certificate : ISO9001 CE

Trade information

* Payment terms : 30%deposite by TT,LC , Western union ,Moneygram

* Delivrey time :Appox 7 working days after receiving the rest payment

* Package : nake ,wooden case

* Warrantty:12 months

* After sales service:we will send 2-3 workers to do the installation and commissioning of the line at the request of the buyer . and the buyer should provide round-trip air plane tickets , accommodation and allowance, the allowance is 70USD /person/day

* HS code :84490090

* MOQ: 1set

Company Introduction :

We are Changshu Hongyi Nonwoven Machinery Co., Ltd with more than 20 years experience in nonwoven machinery field in CHINA. The company has a team of about 100 people including sales, technology and production, covering an area of about 5,000 square meters.

The company's products include but are not limited to needle punching carpet production line, geotextile production line, synthetic leather substrate production line, thermal and chemically bonded wadding production line, automotive interior nonwovens production line and other nonwovens machinery.

Until now, we have established around 100 series of nonwoven machinery production lines all over the countries. Our products have been supplied to more than 20 countries, such as Mexico, Greece, Brazil, Argentina, Turkey, Algeria, Egypt, Bangladesh, Vietnam and so on.

Our company has obtained Utility model patent certificate, Invention patent and CE certificate for our products. In the future, we will continue to work hard to improve the quality of our products and continue to provide customers with our best services.

Related Products

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time