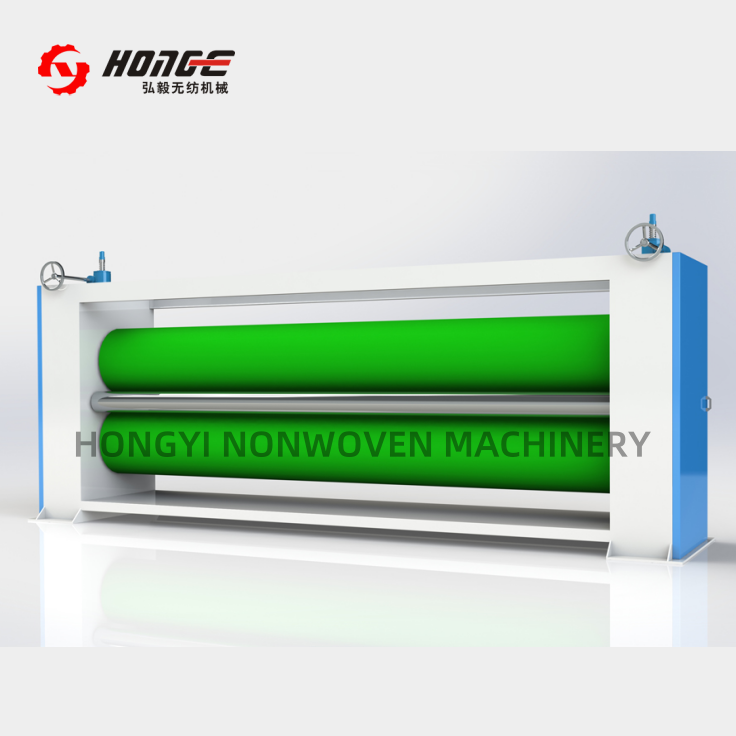

High Capacity Nonwoven Fabric Soft Wadding Thermal Bonding Machine

Category:

Product description

This thermal bonding wadding production line uses low melt fiber or bi-component fiber mixed with normal polyester fiber in properties to create stiff waddings, or such as foam replacements for quilts, cushion, mattress, acoustic and insulation materials, etc.

Product Details

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | HONGYI |

| Certification: | ISO9001/CE |

| Model Number: | HYL-WJM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiation |

| Packaging Details: | PE film or naked. |

| Delivery Time: | 120 days. |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2 or 3 lines per 120 days. |

High Capacity Nonwoven Fabric Soft Wadding Thermal Bonding Machine

Description

| Product Name: | Nonwoven Thermal Bonding Machine For Quilts | Material: | Polyester Fiber, Low Melt Fiber, Wool, Etc. |

| Weight Range: | 60gsm-1200gsm | Usage: | Use Polyester Fiber To Make Soft Wadding Product For Quilts. |

| High Light: | 3500mm Nonwoven Fabric Making Machine, 500kg/h Nonwoven Fabric Making Machine, Nonwoven Thermal Bonding machine | Trim Width: | Up To 3500mm |

| Specfcation Of Fiber: | 3D-15D*51mm-72mm | Production Capacity: | Max. 500kg/h |

High capacity polyester nonwoven soft wadding thermal bonding machine

Production line description:

- This thermal bonding wadding production line uses low melt fiber or bi-component fiber mixed with normal polyester fiber in properties to create stiff waddings, or such as foam replacements for quilts, cushion, mattress, acoustic and insulation materials, etc.

- Also able to make soft wadding for interlinings such as home textiles, garments, furniture, toys, etc.

- The material after forming into a batt is passed through a thermal-bonded oven with stainless steel or teflon belt dependent on the products where fitted the top belt is a movable compression belt.

- However, for soft waddings, eg. lofty material below 1500gram per square meter.

- It is normal to use Teflon belts for the oven machine.

Technical parameters:

| Working width | 1500-3500mm |

| Weight range | 60gsm-1200gsm |

| Raw material | 6D-15D*38mm-51mm polyester fiber, low melt fiber, wool, etc. |

| Process technology | Thermal bonding process |

| Production capacity | max. 500kg/h |

| Applications | quilts, mattress, furniture, garments, insulation materials, etc. |

| Installed power | Depends. |

Trade information:

| Trade terms | FOB, CNF, or CIF |

| Lead time | 90 days after deposit. |

| Payment terms | 30% advance payment, 70% paid off before delivery. |

| Warranty | twelve (12) months after mechanical and electrical commissioning. |

| After-sale service | The seller is responsible for installation and debugging. The buyer is responsible for the round-trip airplane tickets, accommodation, medical treatment, safety and relative fees. In addition the buyers should assign translator, workers, electrical cable (from machines to control panel and from power to control panel) and tools for installation to cooperate with the work. Installation cost is USD180/Day/engineer and totally installation period is about 30-40 days depending on well cooperation of the buyer. |

Key words:

Capacity

Product

Contacts

Tel: +86 18962359051 (whatsapp)

Phone: 86-512-52860355

Fax: 86-512-52860355

Website: www.hongewf.com

Email: rainbow@hongyiwf.cn

Address:No. 52, Jinxiu Avenue, Zhitang Town, Changshu City, Jiangsu, Province, China

Tel:86 18962359051

Phone:86-512-52860355

Address: No.11 Kaicheng Road ZhiTang Town ChangShu City JiangSu Province China

whatsapp:+86 18962359051

Email: rainbow@hongyiwf.cn

We will give you feedback in time